Yorkshire firm -Rotajet Systems - at the heart of recycling revolution

When most of us think about recycling, it’s probably recycling plastic milk bottles, waste paper, and food packaging that immediately spring to mind but one Yorkshire Company is leading the way in designing and manufacturing recycling systems for all manner of things, from car dash boards to used plastic boxes.

Rotajet Systems, based just off the M62 in Wakefield, even helps the McLaren Formula 1 team shred its old car parts, to ensure they do not fall into the wrong hands. Granted, it’s not their main line of work but if another company needs to make sure one of its products is recycled, Rotajet finds a way to make it happen.

Advertisement

Hide AdAdvertisement

Hide Ad“Rotajet Systems can deal with just about anything,” says Colin Steward, 42, co-owner of the business with partner Carl Mason. “Our main lines of work are for washing, cleaning and recycling plastics and other materials. We build machines to enable others to recycle and our machines go all over the world.”

On the back wall of his office is a map of the globe, with little red markers showing locations they have exported to. They range from the UK and Europe to Saudi Arabia, America, Sri Lanka, Africa, Mexico and Australia.

Last year, the company, which employs 25 people, had a turnover of in excess of £ 2.5m and Colin says they hope to double that next year.

Colin left school at 16 to work for a chemicals company and went on to study chemistry at Huddersfield University

Advertisement

Hide AdAdvertisement

Hide Ad“Our order book is full up to the end of the year,” he says. “What we’re seeing is a rapid expansion in recycling, with a lot more orders coming from abroad - 70 per cent of our market is export - but there’s also been a rapid rise in the UK.”

Part of that increase in recycling was due to the decision taken by China last year - known as ‘National Sword’ to ban imports of contaminated plastics from Europe. The ban has forced companies across the globe, who traditionally shipped their unwanted plastics to the Far East, to reconsider what to do with them. All of that means the services of Rotajet Systems are in demand.

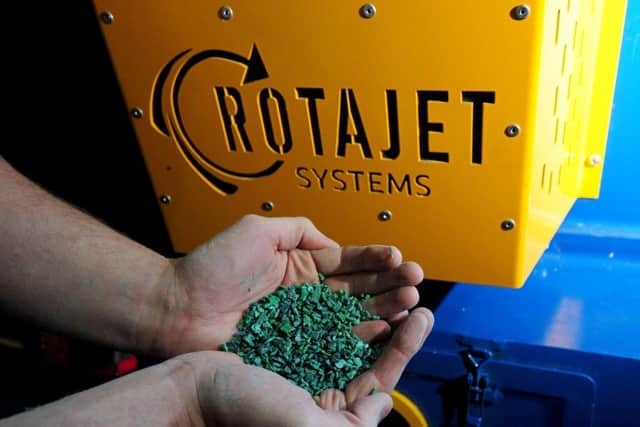

“We’re building machines to recycle the boxes which are used by councils to recycle other waste. So, for example, we have recently supplied a company with a recycling system to take the waste collection boxes which have come to the end of their life cycle and which shreds the boxes in small pieces, which are then washed and made into clean dry granulate, which are then used to make new boxes.”

On the shop floor at their 40,000 sq ft factory, he takes me through the process, which begins with the old, food-stained boxes being placed onto a inclined conveyor, which feeds them into a shredder. The pieces are further ground down, before passing through a series of washers and dryers. What comes out the other end looks like plastic gravel; even the water used in the washing process is recycled.

Advertisement

Hide AdAdvertisement

Hide Ad“It’s a close-looped system,” says Colin. “Councils have a drive to recycle, so now instead of getting rid of their old boxes, they can be use the dry granulate to make new ones.”

But the big news for Rotajet is it has been chosen to work on the European Union’s ambitious Horizon 2020 programme, which is pumping €80bn into research and development to help create new industries and jobs by commercialising laboratory breakthroughs.

One such is the recycling of polypropylene in carpets, a material which has thus far been considered difficult and uneconomical to recycle.

Colin explains: “Carpets contain polypropylene but up to press they have not been recycled. So, they would just be landfilled or burned, which is bad for the environment. What happened was TWI [part of Cambridge University], developed a unique solvent to dissolve polypropylene. They came to us because of our expertise in washing and separation. The project is to isolate polypropylene and then selectively precipitate it out.”

Advertisement

Hide AdAdvertisement

Hide AdColin and Carl founded Rotajet Systems in 2009 after a management buy-out from the previous owners, Colin has a background in chemistry, Carl in engineering. What began as a degreasing business - washing chemicals from containers - has metamorphosed into something far more wide ranging. Now they design, build and ship custom made systems, from shredders to washers, around the world and are in talks to have their products licensed for the manufacture in the USA.

Clients include the likes of Rolls Royce, the rail industry, BASF, paints companies such as, PPG ,Sherwin Williams and Akzo Nobel, De La Rue printers and BAE systems to name just a handful. They’re also proud to have offered a number of apprenticeships at their factory and have plans to expand production, creating another 10,000 sq ft of floor space, within months.

“We’re seeing an upturn in recycling, with a major focus in the plastics sectors” says Colin. “There’s an appetite for it, which has come from the ground up and we have the expertise to enable companies to introduce cost effective systems which ultimately help clean up the environment.”