Pipe maker John keeps up long tradition

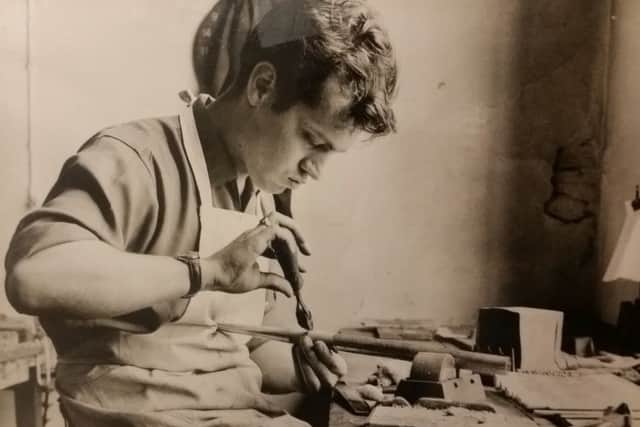

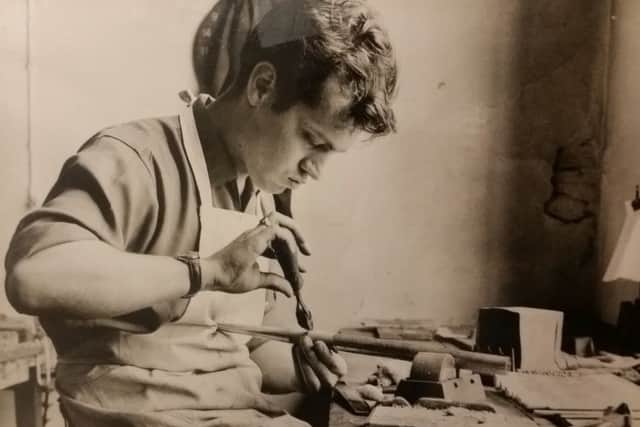

There can’t be many people who can claim to have been in the same job all their life but John Warr can and at 79, he’s still in it. He left school on July 15, 1953 and by August 10, he was working as an organ pipe maker for Bramley-based F J Rogers (which closed in 2004).

Already well past official retirement age, you might think John would be sitting at home with his feet up but he is still in the trade, although he now works one day a week for Shires Organ Pipes Ltd, Mill Lane, Bramley, which is run by Terry Shires.

Advertisement

Hide AdAdvertisement

Hide Ad“I had a few days as a decorator,” recalls John, who is married to Kathleen and has two daughters and two grandchildren. “But he made me clean a ceiling using some powder and when I went home I had a rash and my mother said ‘You’re not going back there.’

“My father knew the managing director at F J Rogers at the time and that’s how I got an interview. I ended up working there and then when Terry started up, I came to work for him.”

The connection between the two runs deep, because John actually trained Terry when they both worked for F J Rogers.

I’m so proud of the heritage and how Terry has now taken it a step further. The business they have now is unique. In some ways, it hasn’t changed at all, in that we still do everything by hand. We don’t use power tools. But the working environment is a lot better: the lighting for a start, I used to work by a 60-watt bulb and I was working 44-hour week, that was basic, then there was overtime on top, we used to finish at seven at night and work Saturday mornings.

Advertisement

Hide AdAdvertisement

Hide Ad“When I started, there were people working who had fought in the First World War and some of them were following in their father’s footsteps, so they went back to the 1800s. Some of the tools we have and still use to this day date from that time. We all know one another, I’m proud to work here.”

During his spare time, John says he enjoys walking, lake fishing, gardening, he even helps look after his 94-year-old mother-in-law. “You have to keep busy,” he says, sagely. “That’s why I want to keep coming here, to keep in touch with my lads, because they are like family to me. I’ve known them since they were young. I know their families and they know mine. If they need help, I give it, if I need it, they help me.”

But even his long service is possibly not the most startling thing about a business which has assiduously avoided the trappings of modernisation.

Walk through the workshop at Shires and nary a power tool will you see - everything here is done by hand, in time honoured tradition. While the temptation in previous years might have been to modernise, perhaps by introducing machines and technology, the fact Shires chose to walk a different path, one which pays homage to hard-won skills learned in a bygone age, is now the very thing which marks them out as unique.

Advertisement

Hide AdAdvertisement

Hide AdBearing in mind they make organ pipes for some of the most prestigious buildings in the world, including the OBE Chapel organ in St Paul’s Cathedral, replacing 3,500 pipes in Manchester Cathedral and others across the world including in America, Australia and New Zealand, it’s astonishing they have stuck so rigidly to tradition.

In fact, conditions in the workshop are pretty much as they would have been 50 or even 100 years ago. When it comes to making organ pipes, however, that’s no bad thing, as owner Terry Shires explains.

Terry, whose son Chris, 22, started working for the company four years ago, was rapturous about John still working in the business.

“To me, he’s invaluable,” said the 58-year-old. “At this moment in time, we’ve got the best crew we’ve ever had. Everyone knows what they’re doing, the quality of skill is unbelievable and that’s borne out by the fact that when cathedrals and universities throughout the world want a new organ or one repairing, invariably they come to us.

Advertisement

Hide AdAdvertisement

Hide Ad“John’s memory is phenomenal, so he’s a real asset for us. If ever a job comes in which is a bit unusual, I will go to him and ask him for advice and odds on he will have worked on something like it.

“We were all taught by John. He worked with all of us at F J Rogers. John taught George [who is 70], who taught Steve and so on... so it goes on today with my son Chris.”

Many of the tools used in the workshop are also made by hand “because they don’t make them anywhere else”, according to Terry, who recalls an interesting anecdote about John’s tools.

“John always had the best tools, but when he left F J Rogers he was selling them and I couldn’t afford them at the time, so they ended up going to a company in Durham. When Chris started here, John said he ought to have had the tools and so we phoned them up and told them the story and they were kind enough to give us the tools back, so they’re back here, still being used.”

Advertisement

Hide AdAdvertisement

Hide AdJohn also recalls the time he went to work on the fire-damaged organ in York Minster, following the fire in 1984.

“I helped to put that back together. The pipes melted, in some cases only half the pipe was left. Where they could be repaired, we repaired and we replaced the others.

“We found an inscription on one pipe from 1828 - 200 years from now someone else will pick that up and see it again.”

John, who is also a member of Bramley Elderly Action, also has fond memories of living in the village as a child, with his two sisters and three brothers.

Advertisement

Hide AdAdvertisement

Hide Ad“My mother was air warden, so when the sirens went off, she went to unlock the Co-op cellar in Bramley and because I was so young, I would go with her. I remember when Bramley was a proper village with herds of cows being driven down the street and surrounded by fields.”

FACTFILE

The expression ‘pulling out all the stops’ is related to organs, which has a series of draw stop nobs, each of which releases 61 pipes to the keyboard. Pulling them all out means ‘full organ’

Organ pips have various component parts, which are named after parts of the body, such as the foot, toe, mouth, body, ears and tongue

The oldest traditional organ in the world is 1440 in Germany, the tree being felled in 1410 - it still plays to this date

Contact Shires Organ Pipes Ltd on 0113 2190221